Chin chin cutting machine is a food processing equipment specially designed for making chin chin, a traditional Nigerian snack. It cuts the dough that has been kneaded into uniform pieces, which then go into frying or other processing steps.

Advantages of chin chin cutting machine

Standardized production: equipped with precision cutting components, it can ensure that the size and shape of each piece of chin chin is the same, improving the consistency and beauty of the product.

Efficient production: can quickly and accurately cut the dough sheets into block or strip chin chin, greatly improving production efficiency.

Save labor costs: compared with manual cutting, chin chin cutter machine can save a lot of labor costs, reduce labor intensity, and improve production efficiency.

How does chin chin cutting machine work?

What you need to know about cutting principles?

The core of the cutting machine is one or more sets of knives that quickly and accurately cut the dough into small pieces according to a set size and shape (usually blocks, diamonds, or rectangular bars). The movement of the tool is rotary.

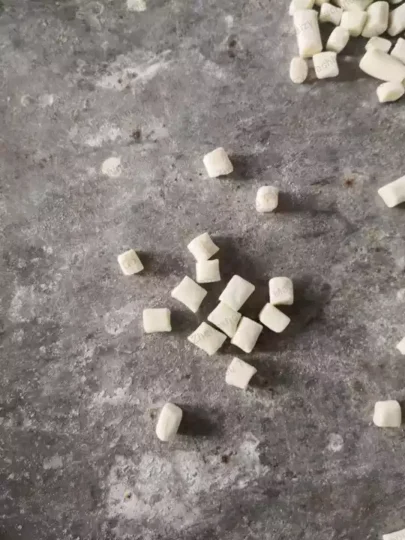

The shape and size of chin chin can vary slightly according to personal preferences and production habits. Some are made into small granules, while others are made into larger cubes.

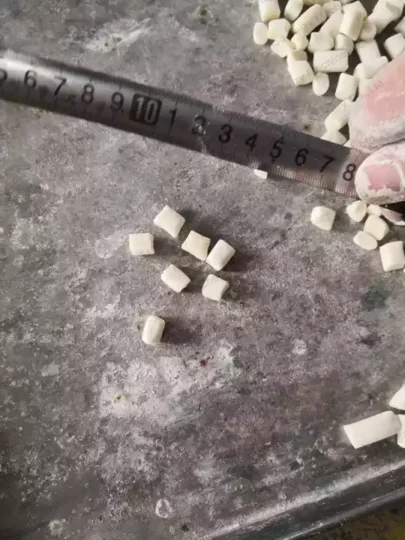

Block-shaped chin chin: the thickness range is from 1.5 to 20mm, and the commonly processed sizes are usually 10, 12, and 15mm, and other thicknesses can also be produced. The length can be adjusted arbitrarily.

block-shaped chin chin

block-shaped chin chin chin chin cubes

chin chin cubes

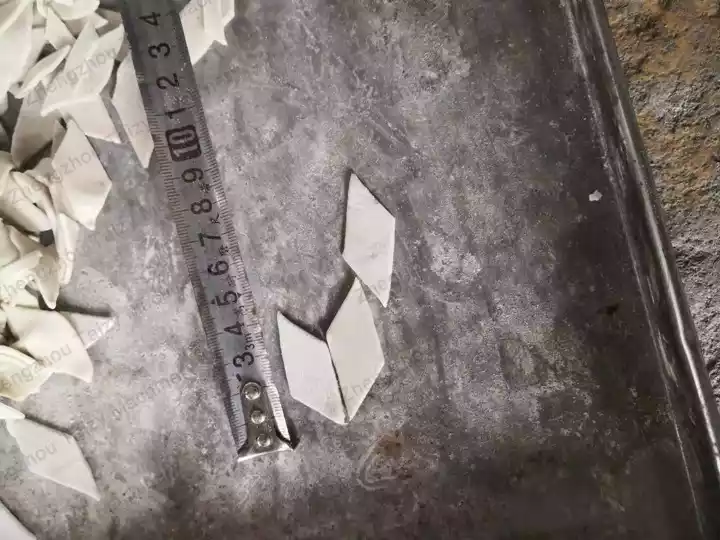

Diamond-shaped flake chin chin: the thickness ranges from 1 to 2mm, usually in flake shape, so it is relatively thin. The length and width can be customized.

1.5cm width

1.5cm width 4cm long

4cm long

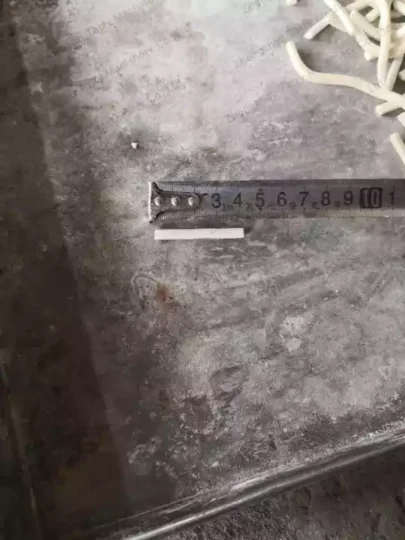

Strip chin chin: the thickness range is 1.5-20mm. The length is within 12cm, the general size is 7,8cm, and the width is usually 3 4 5 6 7 8 10 12 15mm.

strip chin chin long

strip chin chin long strip chin chin thickness

strip chin chin thickness strip chin chin width

strip chin chin width

Types of chin chin cutter machine

Semi-automatic chin chin cutter machine

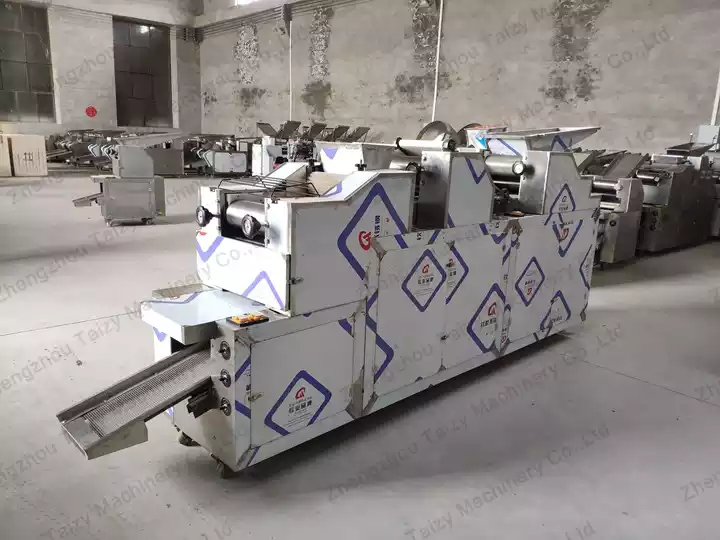

The semi-automatic chin chin cutting machine is usually the key unit in the chin chin production line. It cuts the dough pieces processed by the dough sheeter machine into chin chin shapes for the next step of frying.

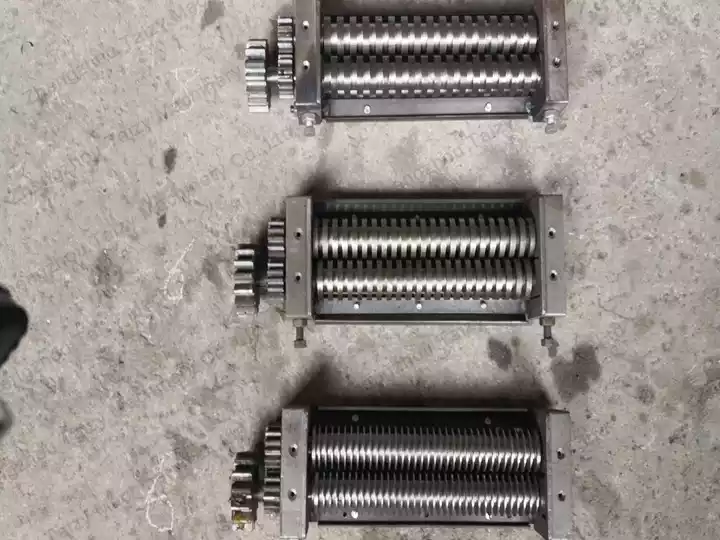

The shape of chin chin can be customized by customizing different cutters. Therefore, if you want to produce chin chin of different shapes, it is recommended that you purchase multiple sets of blades.

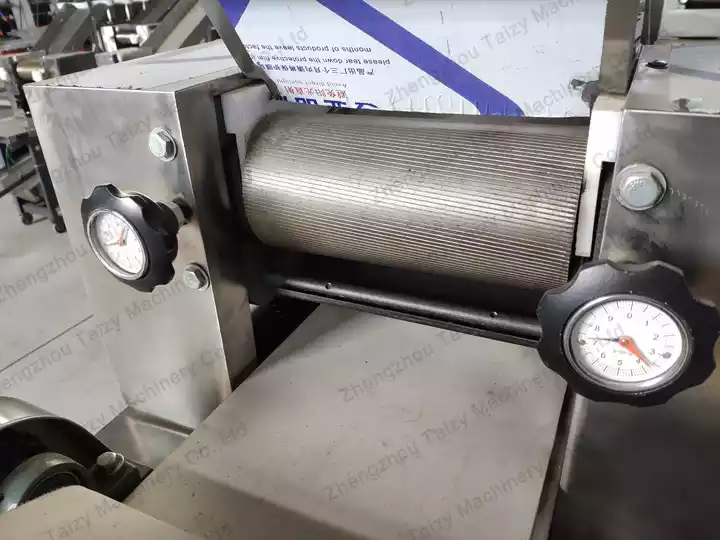

The noodle rollers are squeezed to form dough pieces. By adjusting the gap between the noodle rollers, dough pieces of different thicknesses are formed. After cutting, chin chin of different thicknesses are formed.

semi-automatic chin chin cutter

semi-automatic chin chin cutter blades type

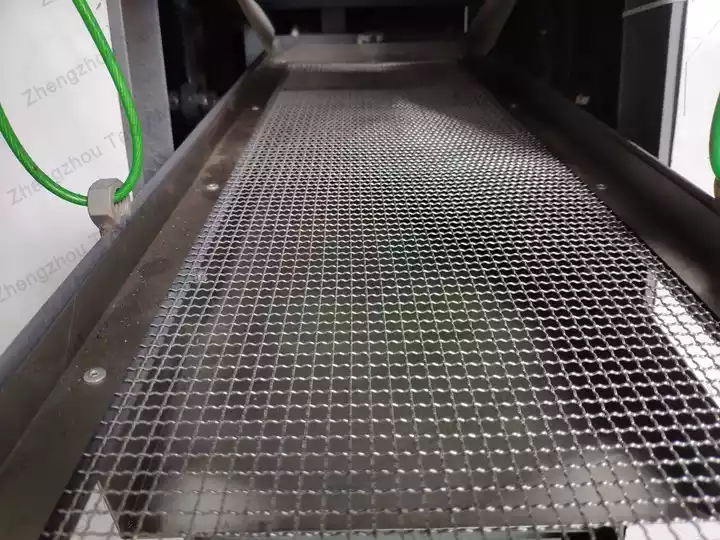

blades type conveyor belt

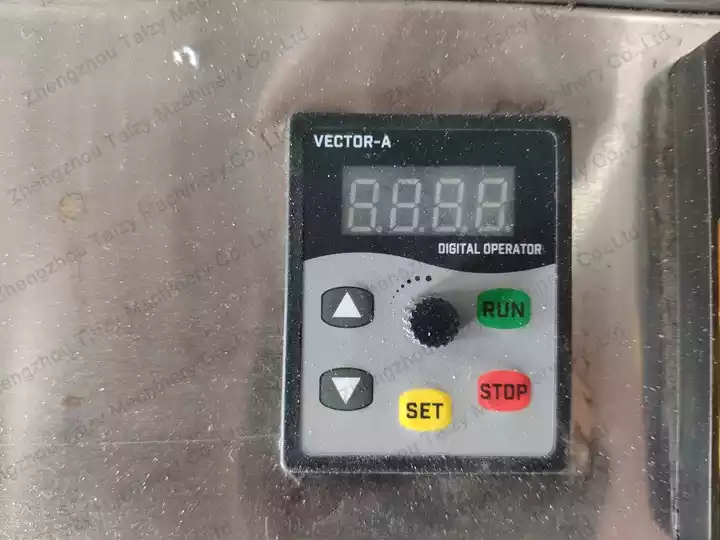

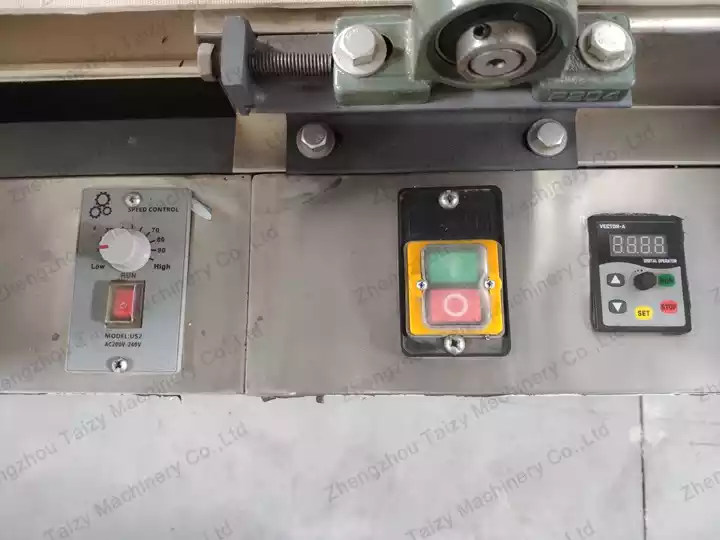

conveyor belt work button

work button

Automatic chin chin cutter machine

Different from semi-automatic chin chin cutting machines, fully automatic chin chin cutting machines do not need to process the dough before cutting, but directly process the dough while cutting, which is more efficient and automated, eliminating the need for a dough sheeter machine.

The inlet is the finished dough. The fully automatic chin chin cutting machine processes the dough into smooth, uniformly thick dough sheets, and then cuts it into chin chin of different shapes.

The fully automatic chin chin cutting machine also includes an automatic flouring function, which can prevent chin chin from sticking and does not require manual operation.

automatic chin chin cutter

automatic chin chin cutter automatic chin chin cutting machine

automatic chin chin cutting machine control button

control button dough roller

dough roller

Technical Parameters of chin chin cutting machine

| Model | TZ-150 |

| Voltage | 380v,50hz |

| Power | 1.5KW |

| Capacity | 150-300kg/h |

| Weight | 280kg |

| Width Range | 1.5-15mm |

Successful cooperation with Nigerian customers

Chin chin is a popular traditional snack in Nigeria. With the advancement of globalization, more and more international diners have begun to understand and like this delicious traditional Nigerian snack, and the market has also been greatly expanded.

Taizy Machinery has already sold many machines related to chin chin production. Besides the production line, the most popular machine is the chin chin cutting machine. Our Nigerian customers are impressed by the quality of our machines and the excellent service, which has also brought profits to them.

chin chin cutter sold to Nigeria

chin chin cutter sold to Nigeria shipped machines

shipped machines

Learn more about the machine

If you still have questions about this machine, or you want to know more information about this machine, please feel free to contact us. We provide the most professional round-the-clock consulting services.