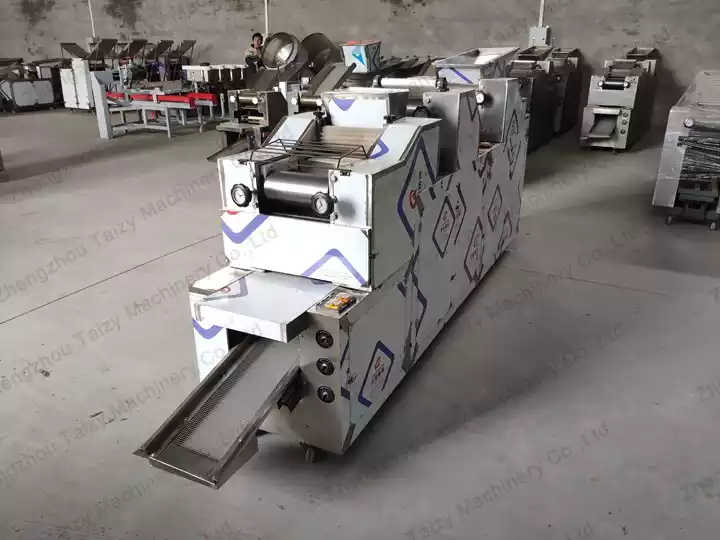

Chin chin cutting machine is an automated pastry food processing equipment. Its efficient and precise cutting of dough brings great convenience to chin chin production. When using a chin chin cutting machine, mastering some techniques can further improve efficiency and product quality.

Dough texture and thickness

Before feeding the dough into the chin chin cutting machine, make sure the dough is moderately soft or hard. Too hard or too soft dough will affect the cutting effect. The dough should be kneaded in advance until it is even and has no large particles.

Use a dough sheeter machine to roll the dough to a consistent thickness. This will ensure that the cut chin chin is consistent in size and thickness, which is beneficial for even frying.

Correct operation of chin chin cutting machine

Feed the dough into the cutting machine flatly, keep the feeding speed even, and avoid being too fast or too slow, so that the cut chin chin pieces will be more even.

When using a chin chin cutting machine, be sure to follow safe operating procedures, such as wearing protective gloves, avoiding direct contact with running parts with your hands, and ensuring that the machine comes to a complete stop before cleaning and maintenance.

Machine maintenance and care

Thoroughly clean the cutting machine before and after use, especially the blades and parts that come into contact with the dough, to avoid hygiene problems and dulling of the blades caused by dough residue. Regularly check the sharpness of the blade, check the wear of the cutting tool, and promptly replace seriously worn blades to maintain cutting quality and reduce the scrap rate in production.