The ice cream cone making machine can complete the baking, shaping, and curling process of the cone to make ice cream cones for filling ice cream. Widely used in ice cream shops, food processing factories, and other places, it not only improves production efficiency but also ensures the standardization and hygienic safety of cones, providing consumers with beautiful and delicious ice cream carrying containers.

Advantages of wafer cone making machine

- Materials and structure: the ice cream cone machine is made of food-grade stainless steel, especially the parts that come into contact with food, to ensure food safety and hygiene during the production process. This material is corrosion-resistant and easy to clean, extending the life of the machine.

- Efficient production: for example, some models can produce 2,000 cones per hour. The high-speed production efficiency can meet commercial needs and is suitable for use in ice cream shops, dessert shops, or food processing plants.

- Size and customization: ability to make cones of different sizes, and molds can be customized to suit different product needs and market preferences.

- Easy to operate: it is easy to learn and can usually be operated by one person, which reduces labor costs and training difficulty.

- Floor space and return on investment: considering the limitations of commercial space, such machines are often compact in design, occupy a small area, and have low investment and quick results, helping to quickly recover costs.

How does the wafer ice cream cone making machine work?

What type of ice cream cone machine can we make?

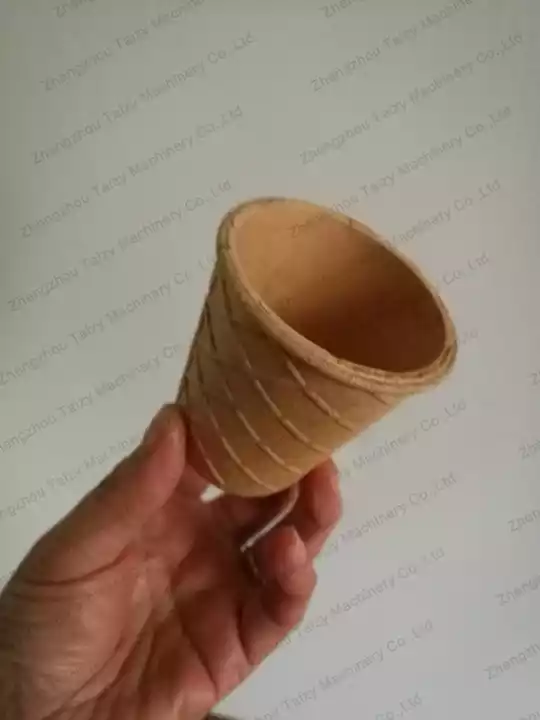

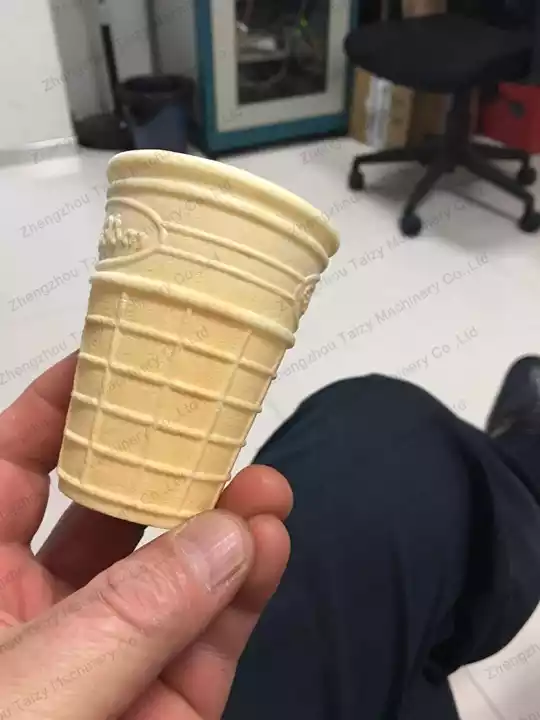

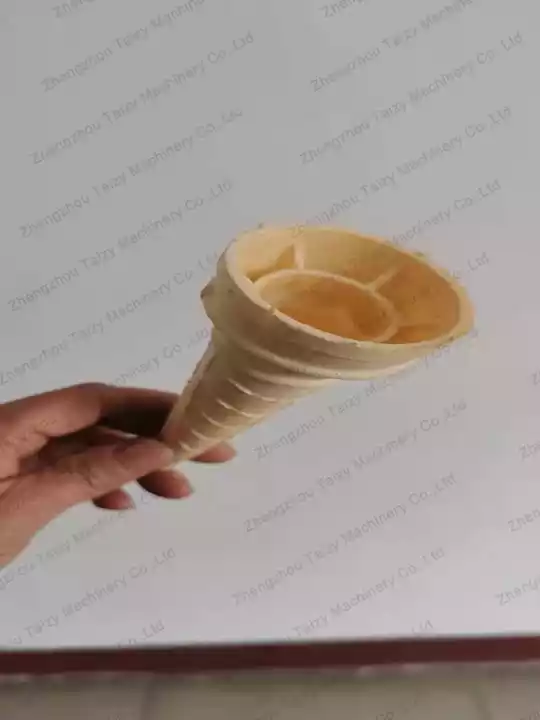

We provide different cone shapes, the common ones are torch type, horn type, cup type, bowl type, and coffee cup type. Sizes and shapes can also be customized. If you want to customize a special cone shape, you need to provide mold technical drawings, and we will build the mold according to the drawings.

This is the finished picture feedback sent by our ice cream cone making machine customer.

cup ice cream cone

cup ice cream cone ice cream cone

ice cream cone ice cream wafer cone

ice cream wafer cone torch ice cream cone

torch ice cream cone wafer cone

wafer cone wafer cup cone

wafer cup cone

Technical parameters of all wafer cone machines

The number in the model name (e.g. 02, 04, 32, 40) indicates how many ice cream cones can be produced at one time.

Our ice cream cone making machine is semi-automatic, meaning it requires a worker to operate it, regardless of the machine model.

All models support electric heating only.

| Model | TZ-02 | TZ-04 | TZ-10 | TZ-12 | TZ-24 | TZ-24C | TZ-32 | TZ-32C | TZ-40 | TZ-40C | TZ-60 |

| Voltage(v) | 220 | 220 | 220 | 220 | 220/380 | 220/380 | 220/380 | 220/380 | 220 | 220/380 | 380 |

| Power(kW) | 1.5 | 2.4 | 5 | 7 | 12 | 12 | 13.5 | 15 | 12 | 18 | 26.8 |

| Capacity(pcs/h) | 50-60 | 100-120 | 250-300 | 300-350 | 600-800 | 600-800 | 800-1000 | 800-1000 | 1200-1400 | 1200-1400 | 1800-2000 |

| Shapes | Horns/Torch/ Cup | Horns/Torch/ Cup | Horns/Torch/ Cup | Only Horns | Horns/Empty Cup | Horns/Torch/ Cup | Horns/Empty Cup | Horns/Torch/ Cup | Mini Horns/Torch | Horns/Empty | Horns/Torch/ Cup |

| Machine Size(mm) | 450*350*700 | 530*430*650 | 760*600*1050 | 800*700*880 | 1050*800*900 | 730*800*1370 | 1200*800*900 | 880*800*1380 | 800*700*880 | 1080*800*1140 | 1550*1000*2000 |

| Packing Size(mm) | 500*400*770 | 570*520*770 | 970*680*1200 | 940*760*1070 | 1140*960*1150 | 890*820*1500 | 1280*960*1150 | 900*1000*1540 | 940*760*1070 | 1180*920*1650 | 1650*1150*2400 |

| Net Weight(kg) | 45 | 80 | 200 | 180 | 280 | 350 | 320 | 450 | 240 | 600 | 1400 |

| Model Size(mm) | 160*108*176 | 302*105*176 | 405*195*185 | 450*190*176 | 574*260*176 | 574*260*176 | 570*330*176 | 570*330*176 | / | / | / |

| Packing Size(mm) | 190*138*210 | 332*140*210 | 435*225*217 | 480*220*210 | 620*320*220 | 620*320*220 | 620*380*220 | 620*380*220 | / | / | / |

| Net Weight(kg) | 23 | 34 | 98 | 114 | 200 | 200 | 225 | 225 | / | / | / |

Key components of ice cream cone maker

Heating system: usually includes electric heating wire, gas burner, or infrared heating element, which is used to heat the ice cream cone mold quickly and evenly, ensuring that the cone skin is baked to golden brown and maintains appropriate crispness.

Control system: the ice cream cone making machine is equipped with an electronic control system that can preset and adjust parameters such as temperature and time. The batter is injected into the same special mold to ensure the consistency and quality of the cone. The wafer cone machine only requires one worker to operate.

Molding system: the mold inside the commercial ice cream maker is designed in the shape of a cone. We provide different cone shapes, the common ones are torch type, horn type, and cup type.

FAQ of ice cream cone making machine

Can the voltage be customized?

We provide voltage customization services, customized according to the voltage standards of the customer’s location.

Which accessories are wearing parts and can be easily replaced?

Our machines are stable and durable. However, some parts need to be replaced regularly due to frequent use and their own reasons: scrapers, feeders, long electric heating tubes, and short electric heating tubes.

Is the finished product soft wafer cone or crispy cone?

It is wafer cone. If you want to make crispy cones, we recommend that you buy our sugar cone making machine. The finished product is crispy.

Welcome to consult more details

If you also want to do an ice cream business or want to run a small ice cream shop, you can contact us to inquire about the details of the machine. We provide 24-hour uninterrupted consulting services, and our professional sales managers and technical team will ensure the stable operation of the machine.