The waffle cone maker machine is a professional device used to make ice cream cones by heating the mold to bake the batter into crispy cone-shaped waffle cones. Ice cream is incomplete without a waffle cone. It is widely used in ice cream shops and dessert shops, giving customers a unique taste.

Different types of finished products waffle cone maker can do

The waffle cone making machine can make regular cone-shaped cones, which can be regular or irregular in diameter. In addition, it can also make waffle cone bowls, waffles, and rolled waffles, which are often inquired by customers and loved by the market.

waffle sugar cone

waffle sugar cone ice cream cone

ice cream cone waffle cone cake

waffle cone cake crispy egg roll

crispy egg roll

How does waffle cone maker work?

The structure and working principle of the waffle cone maker machine

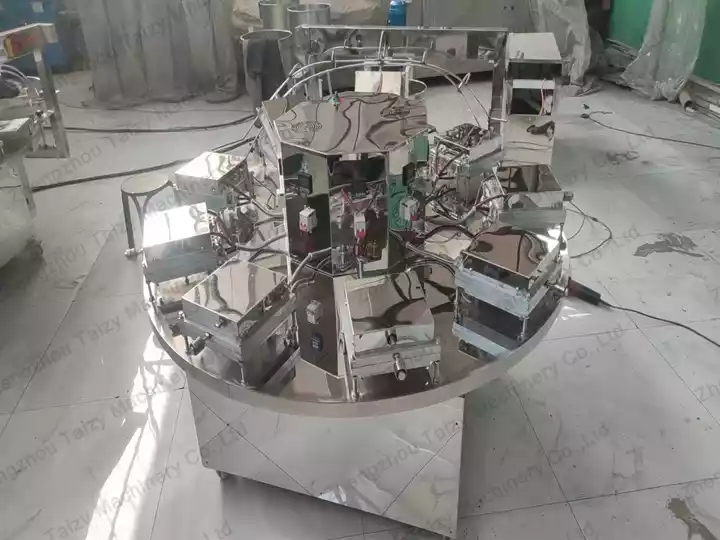

This waffle cone maker machine mainly comprises a heating part and a cone forming part and they work separately.

Heating system

The heating part of the waffle cone machine consists of several independent baking hosts (which means they can work independently). Baking hosts usually include a grouting nozzle and baking pan. The baking host heats the batter into a cake shape.

Each baking host corresponds to a baking pan, and the sizes of each baking pan are different, so multiple waffles can be made at one time. This requires multiple grouting nozzles for each baking pan, so it also needs to be customized. If you want to make a cone-shaped cone later, then enter the shape machine.

According to the customer’s different needs for the shape of the cone, the shape of the baking pan used to heat the batter is also different. It can be a regular waffle grid or a sunflower shape. We provide customers with different options to maximize their personalized customization needs.

The heating system comes with a PLC device that can adjust the temperature and heating time of each part. The operation is simple and customers can adjust it themselves after training.

Automatic cone forming system

Cone forming system is mainly used to make freshly baked waffles into cone-shaped cones, this is a favorite choice in many ice cream shops.

Shaping systems of different sizes can be selected according to different production scales. Normally, a shaping system only contains one conical mold to produce ice cream cones, but if there are a large number of heated waffles, it is recommended that customers choose a shaping machine with double rows of conical molds to improve production efficiency.

Mixing system

The raw materials used to make waffle cones affect the taste of the cone, which in turn affects the customer experience. So this aspect of making the batter is crucial.

We offer additional professional batter mixer machines for making cones. It can evenly mix flour, water, eggs, sugar, and other raw materials into a silky batter. Efficient and large-capacity, it can produce a lot of ice cream cone batter at one time.

Technical parameters of waffle cone maker machine

This machine is divided into electric heating and gas heating. Different models can provide different heating methods. Except for the TZ-06 waffle cone machine which only supports electric heating, the other models can choose from both heating methods.

Regarding the naming of the cone machine model: the number represents the number of baking pans per machine, which means the number of heating components that can be processed simultaneously. The higher the number, the more efficient it is and the more sugar cones can be produced per hour.

Due to the large output of TZ-12, TZ-15, and TZ-18 waffle cone maker machines, they are often paired with double-row cone forming system.

| Model | TZ-06 | TZ-9 | TZ-12 | TZ-15 | TZ-18 |

| Piece thickness(mm) | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

| Piece size(mm) | 7-20 | 7-20 | 7-20 | 7-20 | 7-20 |

| Capacity(pcs/h) | 300 | 400-600 | 600-800 | 800-1000 | 1000-1200 |

| Natural gas(m³) gas-heated | / | 0.6 | 0.8 | 1.1 | 1.4 |

| Liquefied gas(kg) gas-heated | / | 0.9 | 1.2 | 1.4 | 1.6 |

| Power(kW) electric-heated | 10 | 14.5 | 19 | 23 | 28 |

| Dimension(cm) | 140*140*125 | 160*160*125 | 195*195*170 | 205*205*175 | 215*215*170 |

| Weight(kg) | 250 | 270 | 300 | 330 | 360 |

FAQ of sugar cone making machine

Can the shape of the waffle cone be customized?

The shape of the finished product depends on the shape of the mold. If the customer wants to customize waffle cones of different shapes, they only need to customize the mold. Many customers choose to customize their brand logo on the cones.

Can the thickness of each waffle be adjusted?

The thickness range is 0.5-4mm, depending on the amount of batter ejected from the batter nozzle.