Cookies have a certain status in the baking industry and are deeply loved by bakers and consumers. The cookie maker machine is a kind of baking and processing equipment that can efficiently produce standardized cookies. Its appearance has changed the traditional way of making cookies.

3 ingredient butter cookies

3 ingredient butter cookies best sugar cookie

best sugar cookie sugar cookie

sugar cookie butter cookies

butter cookies

Introduction of cookie making machine

Our cookie making machine can make cookies in batches and can be precisely formed and automatically arranged. It can produce up to 180kg of cookies in one hour. It is suitable for applications such as large food processing plants, chain restaurants, bakeries, etc.

This commercial cookie maker includes a digital control panel and transmission device, which is simple, intelligent, and can accurately control the extrusion transmission speed. The mold used to make cookies determines the shape of the cookie, and changing the mold can ensure the diversity of cookie shapes.

The shaped cookies are placed on the baking sheet to await the next step of baking.

How are cookies formed?

First, the cookie batter is prepared as the raw material for the feed port, and then the batter is extruded by the mold into a shape on the baking sheet. The baking sheet moves along the conveyor belt. As the cookies are continuously made, the baking sheet will also move. The speed of the conveyor belt and the speed of the mold making cookies can be adjusted by customers according to their needs.

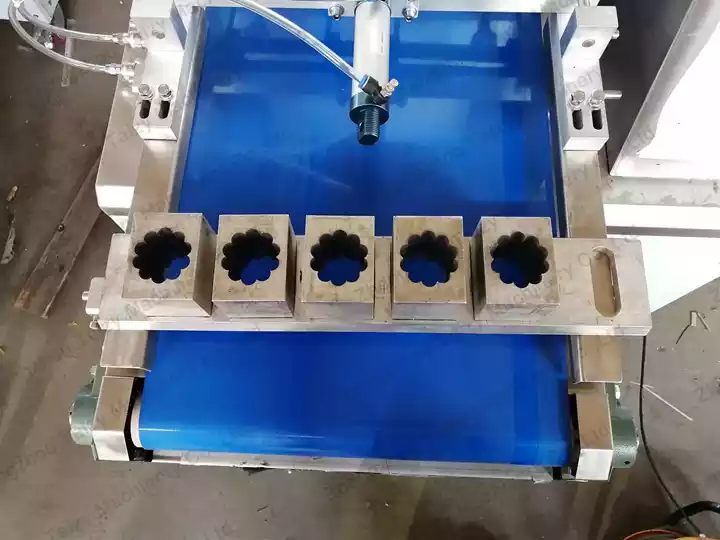

Extrusion mold you can choose

The cookie forming part is mainly completed by mold injection. Different molds and different patterns mean different cookies can be made. Moreover, what is surprising is that the patterns made by the twisting nozzle are very beautiful.

Generally, there are 6 nozzles in a row, but if the customer has additional needs, it can be further negotiated and customized.

We provide the most cookie-shaped nozzle models on the market. If customers have additional requirements, we can provide mold drawings and we can also produce them according to customer requirements.

It’s worth mentioning that the speed and quantity of the nozzle’s output can be controlled by the customer. Additionally, both changing the extrusion molds and replacing the wire-cutting models mentioned below are easy to handle.

Wire cutting model you can select

The wire cutting mold is mainly used to make sheet cookies, and the thickness can also be adjusted by adjusting the discharging speed.

It is formed by cutting steel wire at extremely fast speeds.

Usually, there are 6 in a row.

Specifications of cookie maker

| Model | TZ-400 |

| Power | 1.5kW |

| Voltage | 220v/50HZ |

| Capacity | 100-180kg/h |

| Baking Pan Size | 600*400mm |

| Machine Size | 1460*960*1240mm |

| Weight | 500kg |

| Cookie Wight Range | 2-25g(adjustable) |

| Cookie Size | 1-1.5cm(adjustable) |

How does cookie making machine work?

Advantages of cookie maker machine

- Easy to operate: the cookie maker machine includes an LCD touch panel, PLC control, and computer memory function. It is easy to adjust parameters and is easy to train workers to learn.

- Health and safety: the casing of the whole machine is made of stainless steel, the nozzle mold is designed to be made of aluminum, and the wire-cutting mold is made of steel wire, which is easy to clean.

- Flexibility: adjustable mold speed and extrusion volume, different patterns of cookies.

- Quality control: it can ensure that the quality of the same mold produced under the same circumstances is controllable and consistent, with continuous high-quality output.