Recently, we have reached a friendly cooperation with a food processing company in Chile. They purchased 5 advanced spring roll sheet machines to upgrade their production capacity.

Purpose of purchase: increase production capacity

Chilean customers hope that by introducing an efficient spring roll sheet machine, they can achieve large-scale production of high-quality spring roll wrappers in a short time, reduce production costs, and at the same time meet local high standards for food safety, energy conservation and environmental protection.

Solutions and implementation

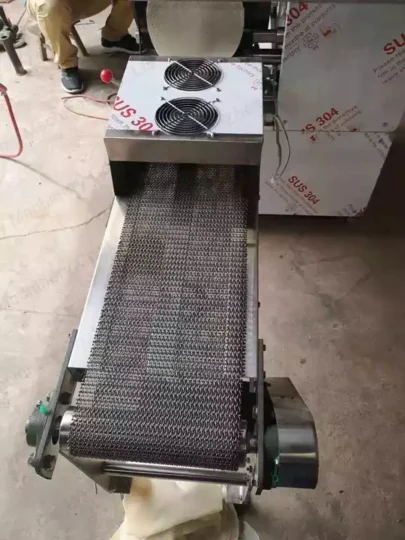

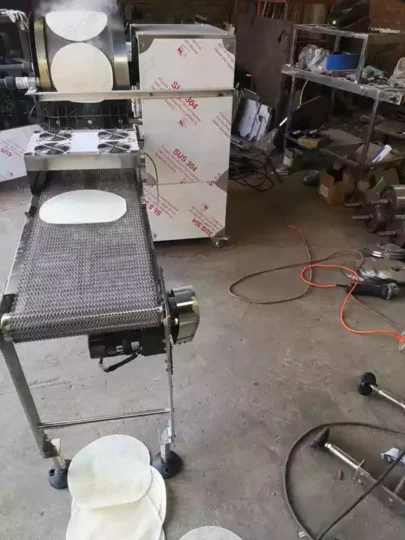

After communication, our manager recommended the TZ-12060 spring roll sheet machine, which uses advanced electric heating temperature control technology and an intelligent control system to ensure the uniform thickness and taste of spring roll wrappers.

After the equipment arrived in Chile, the Chinese manufacturer sent a professional technical team to conduct on-site installation and commissioning and provided detailed equipment operation training and technical guidance to employees of the Chilean company.

Positive feedback from Chilean customer

The spring roll wrapper production capacity has been significantly improved, with daily output increasing by 30%. At the same time, the scrap rate has been significantly reduced, allowing the overall production cost to be effectively controlled.