The batter mixing machine is a machine used in food processing, primarily for mixing and blending batter. It typically consists of a powerful agitator that can quickly and evenly mix ingredients such as flour, water, eggs, etc., to produce a uniform batter.

How does the batter mixing machine work?

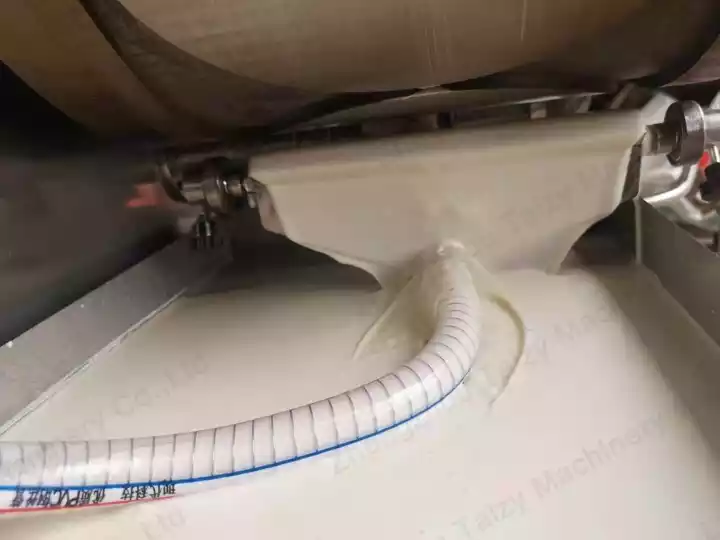

During operation, simply place the ingredients into the mixing tank according to the proportions. After starting the machine, the mixing blades will rotate at a preset speed and direction to ensure that the dough or batter is uniformly mixed without any lumps.

Use in pasta food production lines

The batter mixer greatly simplifies the tedious process of traditional manual batter mixing, improves the standardization and efficiency of pasta production, and is often used in the raw material preparation process of pasta food production lines.

Commercial batter mixing machine parameters

| Model | TZ-30 |

| Voltage | 380v |

| Weight | 80kg |

| Size | 90*40*70cm |

| Capacity | 30L |

Main features of batter mixing machine

The batter mixer is typically made of stainless steel, ensuring durability and easy cleaning, which guarantees hygiene and safety during food processing.

It is equipped with a powerful electric motor and specialized mixing blades, capable of efficiently mixing flour, water, and other ingredients (such as salt, alkaline water, etc.) in a short time to form a smooth and delicate batter.

Structure of batter mixing machine

Mixing tank (cylinder): typically made of stainless steel material, used for loading and mixing dough raw materials. The interior of the tank is smooth and easy to clean to ensure food safety and hygiene.

Mixing device: includes a mixing shaft and mixing blades. The mixing shaft passes through the entire mixing tank and is driven to rotate by an electric motor. The mixing blades are designed according to different dough mixing requirements and can be flat blades, spiral blades, or other special shapes to achieve thorough mixing and blending of the ingredients.

Electric motor: serving as the power source, it transforms the high-speed rotation into low-speed, high-torque output suitable for mixing operations through a reduction device (such as a gearbox), driving the motion of the mixing shaft and blades.

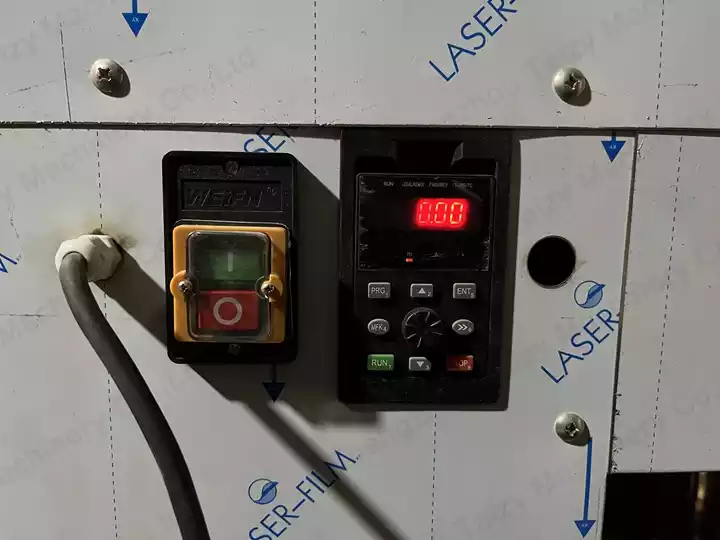

Control system: consisting of power switches, speed regulators, etc., used to start, stop, and adjust the operating speed of the mixer to ensure that the dough mixing process meets the requirements of the product manufacturing process.

Frame and support structure: used to fix and support the mixing tank and main components such as the motor, ensuring stable equipment operation. Our dough mixer can also be customized with personalized casters to facilitate machine mobility.