The Arabic bread production line is a set of efficient food production equipment that integrates modern technology and traditional craftsmanship. It is specially designed for the mass production of popular pasta products in the Arab region, such as pita bread, naan, ciabatta, etc. The production line adopts an advanced automated control system to realize intelligent operation.

Advantage of Arabic bread production line

Efficient automated production: the entire Arabic bread production line is highly automated, from raw material mixing to finished product release, significantly reducing manual intervention and improving production efficiency.

Standardization and consistency: the Arabic bread making machine accurately controls the size and thickness of the dough pieces through the mold, ensuring that every piece of dough and every Arabic bread reaches a uniform standard.

Improved finished product quality: professional ovens ensure even heating, making bread crispy on the outside and soft on the inside. The cooling system allows the bread to cool down quickly, making it easier to package and transport it over long distances.

Working video of Arabic bread production line

FAQ of automatic naan making machine

How do you produce Arabic bread of different sizes?

Different molds can be customized, and the size and shape of each mold can be customized according to customer needs.

Can the oven temperature be adjusted? What is the typical temperature?

The temperature is adjustable and controllable, temperature range: of RT-400℃, baked Arabic bread is usually set at 280℃.

Do you provide a recipe for Arabic bread?

Yes, we provide recipes for regular Arabic bread.

How does the Arabic bread production line work?

To make Arabic bread, you need to prepare the raw materials (dough), press the dough into dough sheets, then shape the dough sheets into the shape of pita bread, bake them in the oven to form hollow Arabic bread, and then cool them. The following are the machines included in the Arabic bread production line:

Dough mixing machine

This is the first step in making Arabic flatbread: preparing the raw materials.

The dough mixing machine body is made of steel and can mix flour, water, or other materials into dough. The dough made by the dough kneading machine is smooth and elastic and is usually used in kitchens, catering restaurants, food processing plants, and other places, and is a hot seller in the food industry.

- Model: TZ-50

- Voltage: 220/380v

- Power: 2.2kW

- Size: 950*530*970mm

- Weight: 134kg

- Capacity: 54L

Dough sheeter machine

The dough sheeter machine can flatten and stretch dough into thin and uniform sheets. It is commonly used in bakeries, pastry shops, and food production facilities to prepare dough for various baked goods such as bread, pastries, pizza crusts, and noodles. The pressed dough is the key to the next step: shaping.

It is worth mentioning that the body of the dough sheeter machine is made of stainless steel and the conveyor belt is PVC grade. The machines we manufacture focus on food health.

- Voltage: 220/380v

- Power: 3kW

- Size: 1035*650*1065mm

- Weight: 245kg

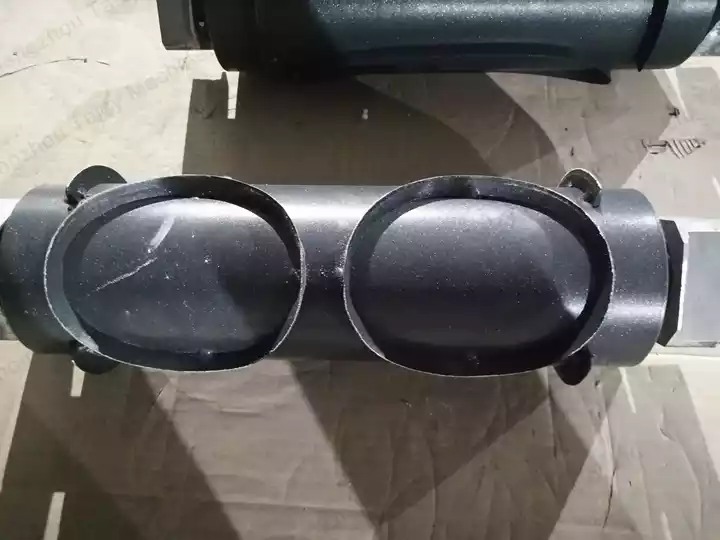

Arabic bread making machine

The Arabic bread making machine is the main machine in the Arabic bread production line and can preliminarily process the pressed dough into the shape of Arabic bread.

We provide excellent personalized customization services, mainly reflected in customized molds. You can choose to make round or square, single row or multi-row, and the diameter and size can be specified, and the thickness can be selected.

Our sales manager will recommend a suitable size based on the shape and number of rows you choose, and we provide services that maximize customer satisfaction.

- Model: TZ-450

- Voltage: 220v

- Power: 3kW

- Model Width: 30cm

- Size: 1700*580*1170mm

- Weight: 400kg

- Capacity: 1500-2000pcs/h

- Thickness: 1-6mm

Pita bread tunnel oven

This Arabic bread tunnel oven can quickly bake and expand flatbread and is used in large-scale Arabic bread production lines.

The tunnel furnace supports gas and electric heating. The internal space is spacious and the heat source is evenly distributed, which allows the bread to be heated evenly in a short time, and allows bread such as pita bread to expand rapidly at high temperatures to form a hollow structure.

The machine includes an intelligent control system so baking time and temperature can be easily set. We can provide layered ovens with chain plates and mesh belts. We provide customers with personalized customization and can provide a wider baking area to process pita bread more efficiently.

In addition to being used to bake Arabic pita bread, it can also be used to bake other similar pasta products, such as naan, to meet diversified food processing needs.

- Model: TZ-530

- Voltage: 220v

- Power: 1.2kW

- Size: 2650*950*1080mm

- Weight: 640kg

- Capacity: 500-1000pcs/h

Cooling machine

- Model: TZ-300

- Power: 700W

- Size: 2500*700*800mm

- Weight: about 150kg

- Material: Full stainless steel

- CBM: 2

Why choose Taizy Machinery?

The Arabic bread production line has the following features:

High degree of automation: the production line tends to be automated from raw material preparation, dough mixing, fermentation, rolling, shaping, baking to final cooling, packaging and other steps, which greatly improves production efficiency and product consistency.

Forming and baking: a high-speed forming machine is used to cut the dough into a suitable size, and then it is quickly baked through high-temperature baking equipment, such as a specially designed pita oven, so that the pie body expands and forms a unique hollow structure.

Customizable: According to different production scales and product needs, the production line can be customized to meet the specific requirements of different customers.

Positive feedback from Arabic customers

The Arab customer contacted us after browsing our website, and our manager listened patiently and answered the details of the machine. Then the customer visited our factory, and based on the customer’s needs, the manager recommended the machine size suitable for the customer.

The Arabic bread production line has been put into production normally, and Arab customers said that our machine has brought them considerable economic benefits.

Our company’s cooperation with Saudi Arabian food companies confirms the competitiveness of Chinese-made food machinery and equipment in the international market.

Welcome to consult us now

Discover how our advanced machinery can revolutionize your bakery operations and elevate the quality and efficiency of your bread production. We also offer round-the-clock support and personalized customization services, ensuring prompt delivery of machines tailored to your needs. Contact us today to learn more!