The automatic flour tortilla making machine is a commercial pasta processing machine, that is mainly used to make tortillas, tacos, Lavash bread, flatbread, Mexico rolls, pita bread, chapati roti, etc. It is widely used in the catering industry and food processing industry. This machine is equipped with an intelligent control panel, which is easy to operate and can produce tortillas with high efficiency and low noise.

Advantages of tortilla making machine

Full automatic, Start from mixed dough, come out lavash bread, no need manual handle, constant temperature baking, uniform color.

- High efficiency: we provide machines with different specifications according to different production scales. Among them, our largest machine, TZ-650 tortilla making machine, can produce an average of 1500pcs an hour.

- Easy to adjust: it contains an electric adjustable system, just one person can operate. You can adjust the diameter (100-400 mm), thickness (0.3-2mm), product color(this depends on the material of the feed port), and speed are adjustable.

- Save for a long time: this machine contains a cold air system that can quickly cool down the finished tortilla, allowing it to be stored at low temperatures for up to one month.

- Other: less maintenance, easy to clean, and low noise.

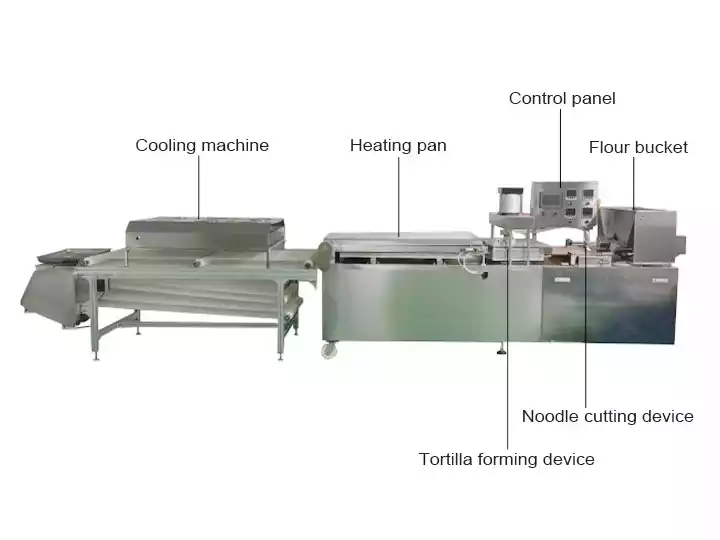

Tortilla making machine structure & working process

The dough mixer mixes flour and water into dough, puts it into the feeding port, and then cuts the dough into small dough. The pressing part presses the small dough into thin pancakes, which are then heated and cooled. The entire process is highly automated, and only the parameters of the control system need to be adjusted before starting. We provide systematic training and explanation on the operation of the control panel.

Inlet/outlet system: the raw material is dough, which can be matched with a dough mixing machine to make dough efficiently. And you can make the finished product you want according to different ingredient recipes.

Molding system: first produce dough from the cutting part of the dough, then press the dough to shape it into a flat round cake shape. The dough’s size affects the finished product’s size, which can be customized according to customer needs.

Heating system: the heating part is made of Teflon material, which has good thermal conductivity, and can promote uniform heating, prevent the cake from sticking, and achieve the required taste and color.

Control system: there is an intelligent panel with simple operation, including temperature control, speed control, and other functions.

Cooling system: after the tortillas are manufactured, they need to be cooled to the appropriate temperature through a cooling belt. And there is also a function of sprinkling flour at the joint.

Successful cases of flour tortilla making machine

The commercial flour tortilla making machines have been successfully sold to Qatar, Mexico, Nigeria, and other places, bringing huge profits and business opportunities to customers. Our machines have good performance, are durable and require almost no maintenance, so they have won unanimous praise from customers. At the same time, our after-sales service is also first-class, and our engineers are very patient with the problems customers encounter.

Commercial chapati making machine parameters

| Model | TZ-350 | TZ-450 | TZ-650 |

| Power | 7kw | 20kw | 30kw |

| Heating method | electric | electric | electric |

| Voltage | 380v, 50Hz/ Customized | 380v, 50Hz/ Customized | 380v, 50Hz/ Customized |

| Capacity | 200-360pcs/h | 700-1200pcs/h | 1400-1800pcs/h |

| Lavash diameter | 80-300mm | 80-400mm | 80-400mm |

| Thickness | 0.3-2mm | 0.3-2mm | 0.3-2mm |

| Working temperature | 150-280℃ | 150-280℃ | 150-280℃ |

| Over Size | 1600*600*1200mm | 5200*800*1400mm | 5200*1050*1400mm |

| Packing weight | 150kg | 420kg | 480KG |