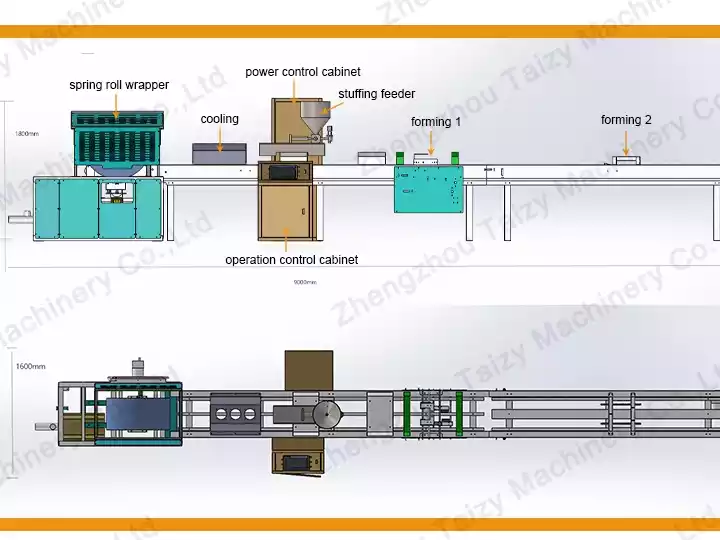

With its high degree of automation, high efficiency, consistency and cost saving, the spring roll production line realizes the automation of a series of processes from dough making to spring roll packaging and is widely used in the food processing industry.

Introduction to spring roll production process

Spring roll wrapper production process: first, flour, water, salt and other raw materials are made into batter by a batter mixer. The batter then goes through steps such as mold pressing, baking, and cooling to make a thin and uniform pie crust. This process is usually completed by a spring roll wrapper making machine.

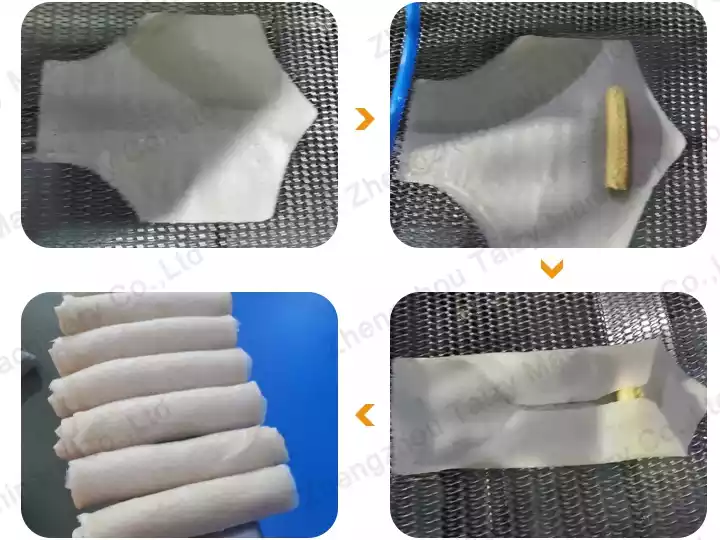

Spring roll wrapping process: spread out the pie crust, add an appropriate amount of fillings, automatically fold the crust, count, and wrap the pie crust into a spring roll shape.

Packaging process: usually completed by automated packaging machinery.

How does the spring roll production line work?

Spring roll production line specifications

We have many models of fully automatic spring roll lines for you to choose from.

| Model | TZ-12060 | TZ-8045 | TZ-5029 | TZ-3060 |

| Host power(kW) | 0.75 | 0.75 | 0.75 | 0.75 |

| Host speed(r/min) | 1-2.5 | 1-2.5 | 1-2.5 | 1-2.5 |

| Dia. of heat roller(mm) | 1200 | 800 | 500 | 400 |

| Conveyor belt power(kW) | 0.55 | 0.55 | 0.55 | 0.55 |

| Productivity(pcs/h) | 4500-7000 | 3000-4500 | 1000-1500 | 500–1000 |

| Size(mm) | 5300×1500×2200 | 5600×1100×1600 | 5200×950×1350 | 4350×800×1200 |

| Weight(kg) | 1450 | 1250 | 650 | 350 |

| Product size(mm) | 5-550 | 5-450 | 5-290 | 5-200 |

| Product thickness(mm) | 0.3-2.0 | 0.3-2.0 | 0.3-2.0 | 0.3-2.0 |

| Voltage(v) | 220/380 | 220/380 | 220/380 | 220/380 |

| Electric heating power(kW) | 50 | 33 | 14 | 8.2 |

| Gas heating power(kW) | 1 | 1 | 1 | 1 |

We support personalized customization, which mainly includes: spring roll wrapper size, square/round shape, voltage standard, and delivery box size, etc.

Gas heating supports liquefied gas or natural gas.

Precautions for spring roll production line

- The machine should be installed on a firm and stable ground.

- During installation, the heating cylinder must be parallel to the axis and the base feet must be firmly padded.

- It is strictly prohibited to use water to wash the electrical equipment.

- Maintenance and repair must be performed with the main switch turned off.

- A small amount of machine oil should be regularly added to the oil hole on the main spindle of the dough pump to prevent damage to the pump.

- After production, clean the dough pump with clean water, including the return pipe, dough tray, dough pump, and dough nozzle.

13mm long soring roll

13mm long soring roll 4mm width spring roll

4mm width spring roll

Advantages of spring roll production line

High degree of automation: the spring roll production line adopts automated equipment and processes to realize a series of processes from dough making to spring roll packaging.

High production efficiency: greatly improves the production speed of spring rolls and meets the needs of mass production.

Save labor costs: compared with traditional manual production methods, the spring roll production line reduces the need for manual labor and lowers production costs.

Hygiene and environmental protection: the spring roll production line reduces the impact of human factors on food hygiene, improves food safety, and meets environmental protection requirements.

Strong flexibility: the spring roll production line can be customized and designed according to customer needs, and has strong production adaptability and flexibility.