Cupcake filling machine, also known as cake cream filling machine, is an automated equipment specially designed for use in the cake production process. It is mainly used to evenly and quantitatively inject pre-prepared cake batter into cake molds. The cake filling machine can make cupcakes, cookies, multi-layered cream cakes, chocolate cakes and other desserts, and is widely used in the baking field.

Main Features of cake cream filling machine

- Accurate batter injection: a precise metering system is used to ensure the accurate weight of the cake batter injected into the mold each time, making the cakes consistent in size and weight, and ensuring product standardization and quality stability.

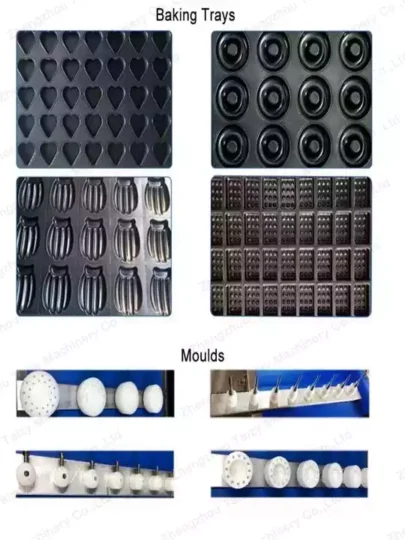

- Versatility: according to different cake molds and product needs, the grouting head can be replaced or adjusted to accommodate cake production of different sizes and shapes.

- Easy to operate: equipped with an intelligent control system, you can set and adjust parameters such as paste injection volume and paste injection speed through the touch screen or buttons. The operation is simple and convenient.

- Safety and hygiene: made of stainless steel, the structural design is easy to clean and maintain, complies with food safety and hygiene standards, and ensures the cleanliness and hygiene of the production process.

- High degree of automation: it can automatically complete the quantitative pouring of cake batter, greatly reducing manual operations and improving production efficiency.

How does the cupcake filling machine work?

What is the structure of the cupcake filling machine?

Feed port

The feed port is in the shape of a hopper and can accommodate up to 60L of batter. The material is stainless steel, which ensures food safety.The raw material for the feed port is batter, or other relatively fluid materials, such as peanut butter, cocoa butter and other jams. This will ensure that the jam can be squeezed out normally.

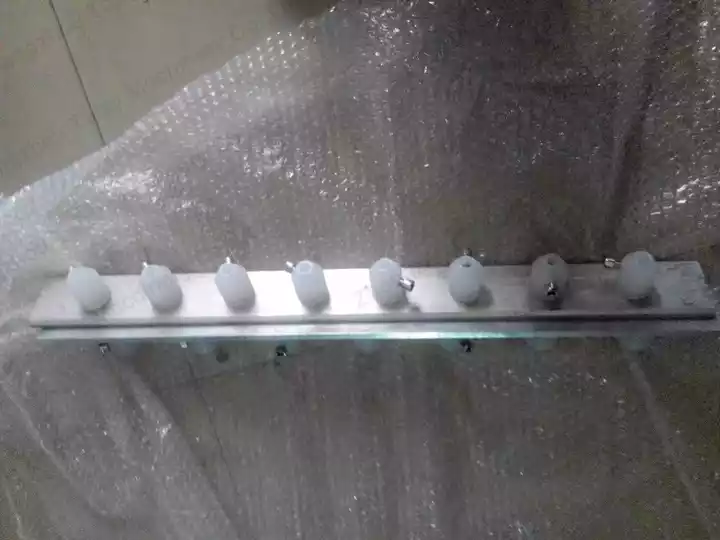

Grouting device

The work of injecting batter is done by a row of nozzles and special molds. The molds are sent to the nozzles on a conveyor belt, and the nozzles spray the batter into the molds.

The material of the mold is an aluminum-plated plate, and the surface is covered with a layer of Teflon coating. This ensures that the batter will not stick to the mold to a certain extent, but it is recommended to grease it before use.

Control System

The control system includes a touch screen, PLC controller, etc., which is used to set and control various parameters of the paste injection machine, such as grouting volume, grouting speed, working cycle, etc.

The injection volume and speed are adjustable, which means the shape of the cake or cookie can be defined at any time.

Transmission and drive systems

An additional air compressor is required to provide a compressor for the grouting machine to ensure the stability and accuracy of the grouting process.

Maximizing customer satisfaction

Customers can design the cake shape they want according to their needs, which is often achieved by personalizing the machine details. We will also provide customers with machine models and machine details that best meet customer needs.

The size and number of nozzles can be customized according to customer needs. The more nozzles, the higher the production efficiency. The size of the nozzle also affects the shape of the cake.

The mold is usually a plate with many shaped grooves. You can change the shape of the cake you want to make by customizing the shape of the grooves on the plate, which is usually round but can also be made into an oval, square, or heart-shaped shape. These can be personalized according to customer needs.

Molds and nozzles are usually matched, and the number of nozzles corresponds to the number of grooves in the mold.

Technical parameters of cupcake filling machine

| Model | TZ-600 |

| Voltage | 220 V/50HZ single phase |

| Power | 1.2kW |

| Capacity | 120-240kg/h |

| Size | 1700*1100*1400 |

| Weight | 380kg |

| Material | stainless steel |