The Arabic bread machine cuts dough sheets of uniform thickness into shapes suitable for Arabic bread, which can be square or round, with adjustable thickness. The finished product is ready for the next step of baking. Due to its high-efficiency production, it is often used in the catering industry and food processing plants.

Advantages of Arabic bread making machine

Standardized production: the length, width and thickness of the dough pieces produced each time are fixed, ensuring the standardized production of Arabic bread, and the consistency and quality controllability of each batch of products are significantly improved. And the remaining dough pieces after shaping can be produced again.

Durable material: made of 201 stainless steel, this material is not only highly corrosion-resistant, easy to clean and maintain, but also wear-resistant, extending the service life of the machine.

Flexibility and diversity: the dough sheets produced are of moderate size, suitable for making a variety of Arabic breads, such as pita bread, naan, chapati, etc., meeting the market demand for different types of Arabic breads, and improving the product’s market adaptability and Competitiveness.

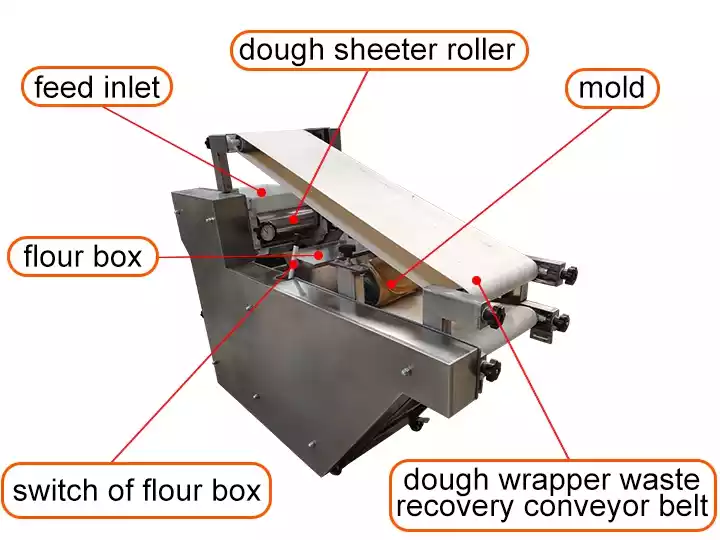

What is the structure of Arabic bread machine?

Feeding: the dough sheeter machine press the dough into a uniform thickness.

Conveyor belt: transfers dough at a certain speed.

Molds: the dough is usually cut into the desired shape and size, such as round or rectangular Arabic bread dough. Both shape and thickness can be adjusted through the mold.

Rotating roller: the remaining waste material after cutting can be pressed and stretched by the roller, gradually becoming thinner and maintaining uniformity. Return to the conveyor belt for the next use.

Flour box: sprinkle flour evenly onto the prepared Arabic bread dough.

Operation Video of Pita Bread Machine

Parameters of Arabic bread machine

| Voltage | 220v |

| Power | 3kW |

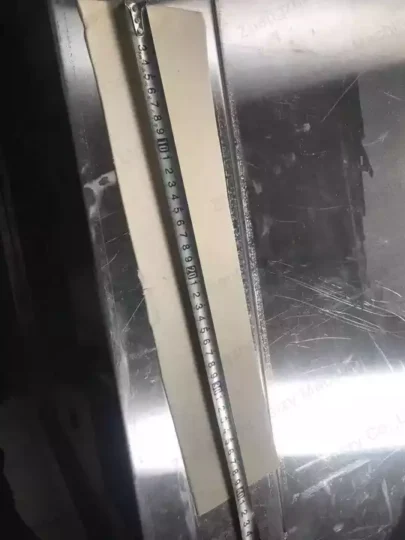

| Model width | 30cm |

| Thickness | 1-6mm |

| Capacity | 1500-2000pcs/h |

| Size | 1700*580*1170mm |

| Weight | 400kg |

What is the process of making Arabic bread?

Making Arabic bread involves these steps, often made from Arabic bread production lines.

Dough processing: first, the machine accepts the pre-mixed dough. After the dough has rested and fermented appropriately, the machine will divide the dough into dough pieces of a certain weight.

Rolling and shaping: the dough pieces are fed into the rolling mechanism through the feeding system, and the dough is evenly rolled and pressed through two upper and lower rollers (rolling pins) with adjustable spacing to form a thin and uniform pie crust.

Baking processing: next, the crust will be sent to the oven, and the crust will be baked and shaped instantly through high temperature, forming a hollow structure inside (especially the iconic pocket-like structure of pita bread).

Packaging and collection: after baking, the Arabic flatbread will be collected and prepared for further packaging or immediate consumption.

Personalized customized services for customers

Wheels: we offer customized wheels for machine movement.

Working speed: you can adjust the production speed according to your needs.

Size and thickness: we can provide square, round, and different sizes, which are determined by the mold.

Product type: the hollow state of the Arabic bread can be achieved by using a customized punching tool on the Arabic flatbread dough.

FAQ of pita bread machine

What material does the machine consist of?

The machine shell is 201 stainless steel, the conveyor belt is 304 stainless steel, and the others are carbon steel.

What is the normal thickness of Arabic bread?

Generally, it is 2mm, our machine can make Arabic breads of 1-6mm.

How to make Arabic bread of different sizes?

Just replace different molds. You can consider purchasing different molds when purchasing the machine.