The spring roll wrapper machine is a food processing machine specially designed for the mass production of spring roll wrappers, injera, and other pizzas. This machine has a variety of heating methods and can be customized into various sizes. It is the host of the spring roll processing production line and can easily make lumpia. We provide our customers with personalized service.

Advantages of spring roll wrapper making machine

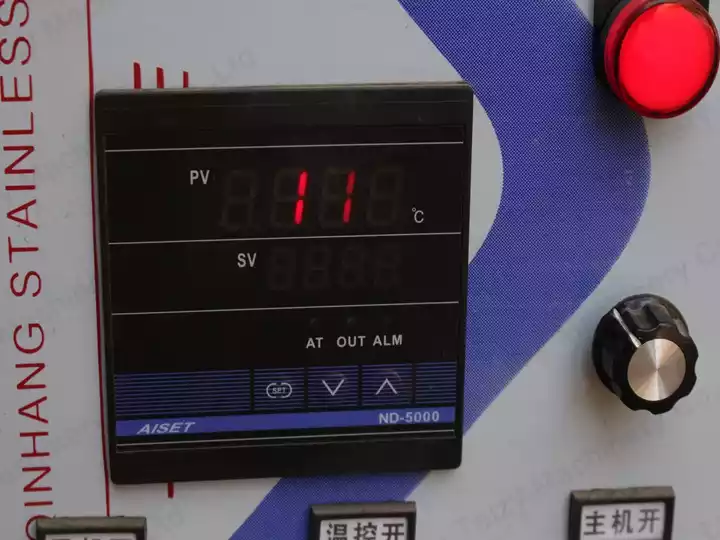

- Using the microcomputer temperature control system, the spring roll sheets have soft hardness.

- The precision of the spray nozzle is high, and the spring roll wrapper is even and thin.

- Fully automatic cutting and folding counting save time and effort.

- The equipment only needs to be lubricated once a year, and it makes little noise and requires no maintenance.

Raw materials and finished products

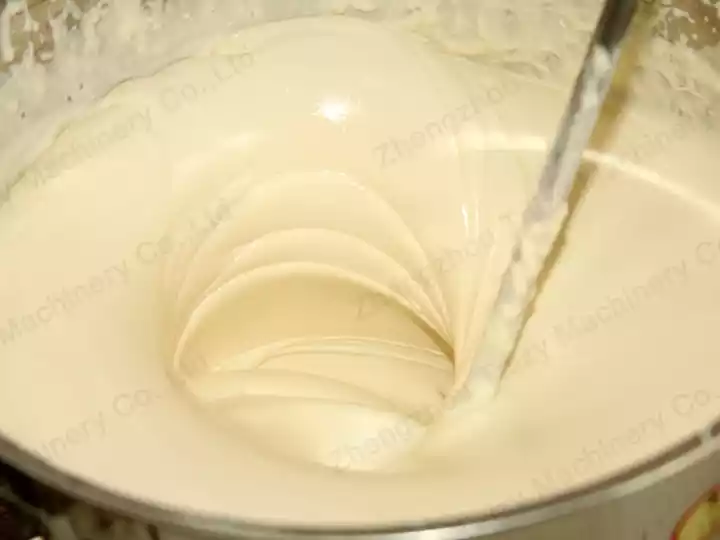

The raw material of the spring roll wrapper machine is batter, which should not be too thick. It may be simpler and more efficient to use a batter making machine.

You can add egg liquid and corn flour to it, and you can also adjust the thickness, size, and shape of the wrapper according to your needs. The finished products include spring roll wrappers, injera, egg rolls, pancakes, etc.

batter as raw materail

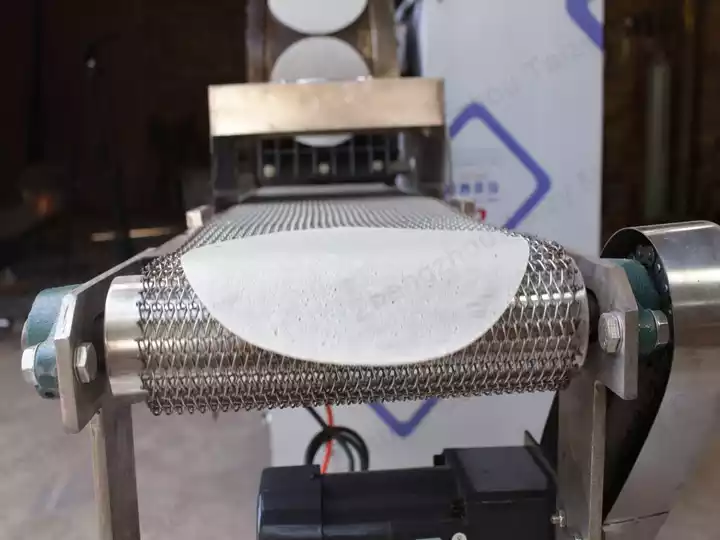

batter as raw materail finished spring roll sheet

finished spring roll sheet

Technical parameter of spring roll wrapper machine

| Model | TZ-3620 | TZ-5029 | TZ-8045 | TZ-12060 |

| Size(mm) | 1800*660*890 | 2400*800*1350 | 2800*1100*1600 | 3100*1300*1800 |

| weight | 260kg | 520kg | 750kg | 850kg |

| Dia. of heat roller | 400*280mm | 500*330mm | 800*600mm | 1200*600mm |

| Electric Power | 6kw | 13kw | 32kw | 48kw |

| Cutting power | 1kw | 1kw | 1kw | 1kw |

| Capacity | 800-1000pcs/h | 1500-2000pcs/h | 3000-4000pcs/h | 5000-6000pcs/h |

| Sheet max size(mm) | Only roll:250 | Roll:350 square:300 | Roll:430 square:450 | 600 |

| Sheet thickness | 0.3-1.2mm | 0.3-1.2mm | 0.3-1.2mm | 0.3-1.2mm |

What’s the structure of the machine?

The spring roll wrapper machine includes a mixing system, a paste feeding part, a main machine, a heating system, a conveying system, a sheet stacking system, and a cooling system.

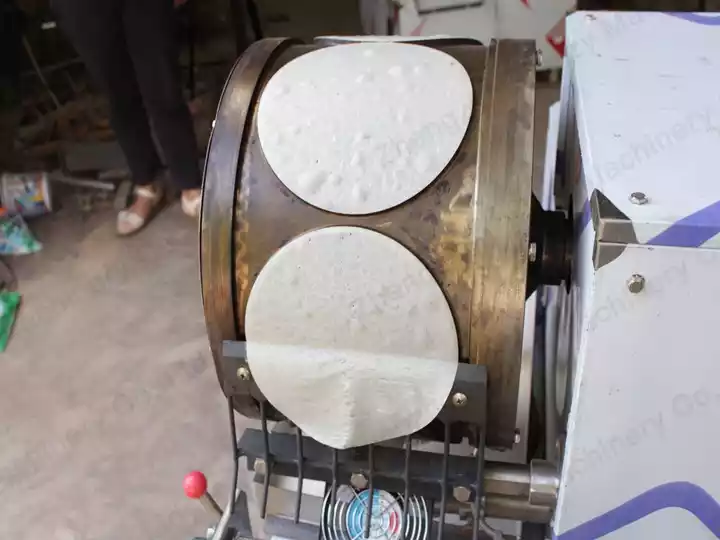

The body is made of stainless steel and complies with food hygiene standards. The roasting wheel is made of special alloy steel and is not deformed.

It also has a cutting part for making square spring roll wrappers. You can also choose to make multi-row or single-row products.

control panel

control panel molding device

molding device

In addition, you can also choose different heating methods, we provide electric heating, gas heating, and electromagnetic heating.

Equipped with a highly automated operation panel, the spring roll wrapper machine can be used to accurately control parameters such as temperature, fan, host speed, and conveyor belt speed. It can be easily operated by one worker.

Spring roll wrapper making process

Precautions for making injera

Injera is a traditional fermented pasta from Ethiopia and Eritrea. When making Injera, you need to pay attention to the selection of raw materials and the fermentation process.

- Add an appropriate amount of warm water and salt to the teff flour.

- Add baking powder and let it sit until the batter becomes sour and foamy. The thicker the batter, the thicker the injera, and vice versa.

- Pour the fermented batter into the feed port of the spring roll wrapper machine, and then mass-produce injera.

finished injera

finished injera injera products

injera products

FAQ of spring roll wrapper machine

Can the same mold be made in different sizes?

No, if you want to change the size, you need to change the heating roller to different specifications.

Therefore, according to the customer’s needs for the size and output efficiency of spring roll wrappers, our managers will recommend the appropriate specifications for you, single row or double row.

Do you have a recipe for spring roll wrappers?

Yes, we offer recipes that produce smooth, even, and soft spring roll wrappers.

What is the ratio of dough to water?

1 kg of flour is equivalent to 1.2 kg of water. Less water will produce thicker spring roll skins, while more water will produce thinner skins. Customers can adjust the proportion of flour and water according to their needs.