La machine à pain arabe découpe des feuilles de pâte d'épaisseur uniforme en formes adaptées au pain arabe, qui peuvent être carrées ou rondes, avec une épaisseur réglable. Le produit fini est prêt pour l'étape suivante de la cuisson. En raison de sa production à haute efficacité, elle est souvent utilisée dans l'industrie de la restauration et les usines de transformation alimentaire.

Avantages de la machine à pain arabe

Production standardisée : la longueur, la largeur et l'épaisseur des morceaux de pâte produits à chaque fois sont fixes, garantissant la production standardisée de pain arabe, et la cohérence et la contrôlabilité de la qualité de chaque lot de produits sont considérablement améliorées. Et les morceaux de pâte restants après la mise en forme peuvent être produits à nouveau.

Matériau durable : fabriqué en acier inoxydable 201, ce matériau est non seulement très résistant à la corrosion, facile à nettoyer et à entretenir, mais aussi résistant à l'usure, prolongeant la durée de vie de la machine.

Flexibilité et diversité : les feuilles de pâte produites sont de taille modérée, adaptées à la fabrication de divers pains arabes, tels que le pain pita, le naan, le chapati, etc., répondant à la demande du marché pour différents types de pains arabes, et améliorant l'adaptabilité et la compétitivité du produit sur le marché.

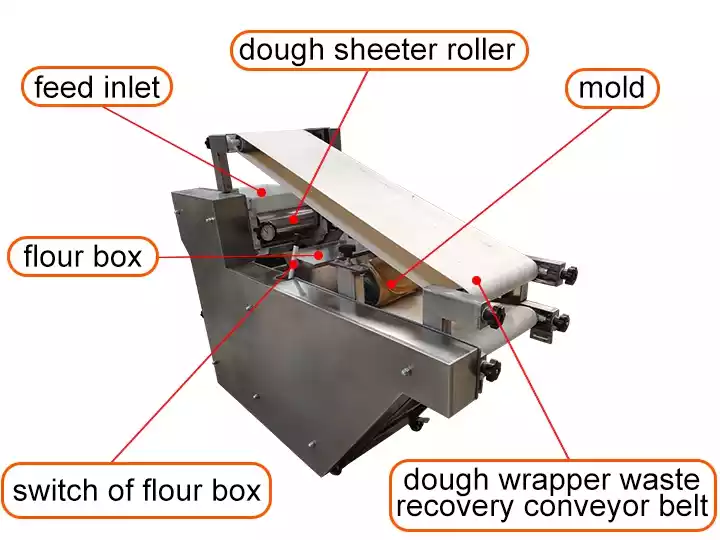

Quelle est la structure de la machine à pain arabe ?

Alimentation : la machine à abaisser la pâte presse la pâte à une épaisseur uniforme.

Bande transporteuse : transfère la pâte à une certaine vitesse.

Moules : la pâte est généralement découpée en forme et taille souhaitées, comme de la pâte à pain arabe ronde ou rectangulaire. La forme et l'épaisseur peuvent être ajustées par le moule.

Rouleau rotatif : le matériau résiduel après découpe peut être pressé et étiré par le rouleau, devenant progressivement plus fin et maintenant l'uniformité. Retourne à la bande transporteuse pour la prochaine utilisation.

Boîte à farine : saupoudrer de la farine uniformément sur la pâte à pain arabe préparée.

Vidéo d'opération de la machine à pain pita

Paramètres de la machine à pain arabe

| Tension | 220v |

| Puissance | 3kW |

| Largeur du modèle | 30cm |

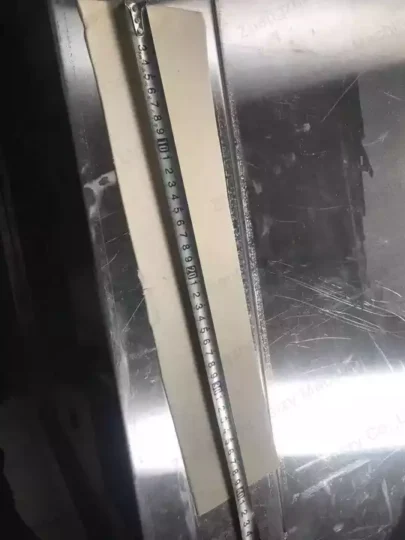

| Épaisseur | 1-6mm |

| Capacité | 1500-2000pcs/h |

| Taille | 1700*580*1170mm |

| Poids | 400kg |

Quel est le processus de fabrication du pain arabe ?

La fabrication du pain arabe implique ces étapes, souvent réalisées à partir de lignes de production de pain arabe.

Traitement de la pâte : d'abord, la machine accepte la pâte pré-mélangée. Après que la pâte a reposé et fermenté de manière appropriée, la machine divisera la pâte en morceaux de pâte d'un certain poids.

Roulage et façonnage : les morceaux de pâte sont introduits dans le mécanisme de roulage par le système d'alimentation, et la pâte est roulée et pressée uniformément entre deux rouleaux supérieurs et inférieurs (rouleaux) avec un espacement réglable pour former une croûte de tarte fine et uniforme.

Traitement de cuisson : ensuite, la croûte sera envoyée au four, et la croûte sera cuite et façonnée instantanément par haute température, formant une structure creuse à l'intérieur (en particulier la structure emblématique en forme de poche du pain pita).

Emballage et collecte : après la cuisson, le pain plat arabe sera collecté et préparé pour un emballage ultérieur ou une consommation immédiate.

Services personnalisés pour les clients

Roues : nous proposons des roues personnalisées pour le mouvement des machines.

Vitesse de travail : vous pouvez ajuster la vitesse de production selon vos besoins.

Taille et épaisseur : nous pouvons fournir des tailles carrées, rondes et différentes tailles, qui sont déterminées par le moule.

Type de produit : l'état creux du pain arabe peut être obtenu en utilisant un outil de perforation personnalisé sur la pâte de pain plat arabe.

FAQ sur la machine à pain pita

De quel matériau est composée la machine ?

Le boîtier de la machine est en acier inoxydable 201, la bande transporteuse est en acier inoxydable 304, et les autres sont en acier au carbone.

Quelle est l'épaisseur normale du pain arabe ?

En général, c'est 2mm, notre machine peut faire des pains arabes de 1-6mm.

Comment faire du pain arabe de différentes tailles ?

Il suffit de remplacer les différents moules. Vous pouvez envisager d'acheter différents moules lors de l'achat de la machine.