As milk tea has become popular worldwide in recent years, Boba pearls are also loved by everyone. The tapioca pearls machine is a food processing equipment specially used for the automated production of boba pearls. The machine is designed to increase production efficiency, ensure pearl quality and taste consistency, and reduce labor requirements. So how much do you know about this machine?

What are tapioca pearls?

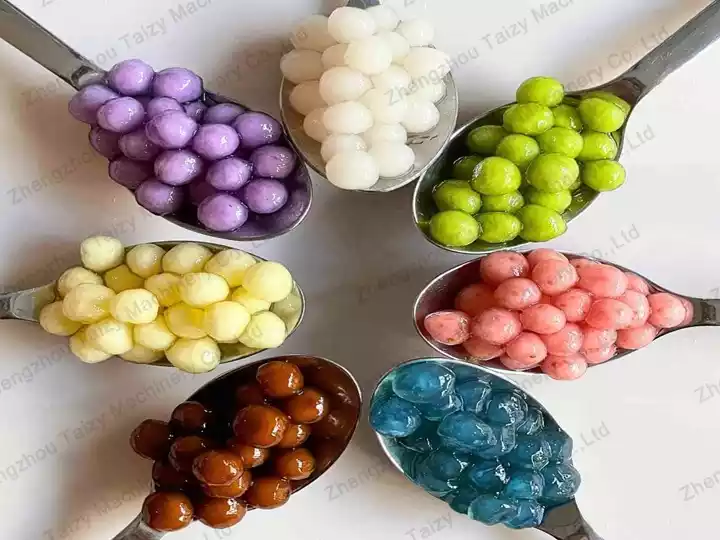

Tapioca pearls, also known as boba pearls, originated from tea shops in Taiwan. Due to their unique taste – chewy and slightly sweet, they quickly became popular in Taiwan. With the advancement of globalization, in recent years, everyone’s love for Boba pearls has rapidly spread throughout Asia and even the world.

Boba pearls are made from tapioca flour, glutinous rice flour, sugar, water, and other raw materials. If you want to make products with great taste, buy a tapioca pearl machine and we will provide the best-selling boba pearl recipe.

How does the tapioca pearls machine work?

Advantages of tapioca pearls machine

High-efficiency production: compared with manual production, a large number of boba pearls can be produced in a short period to meet large-scale commercial needs and are suitable for chain milk tea shops, dessert shops, or food processing factories.

Standardized quality: ensure that the size, shape, and weight of each pearl are the same, and the taste is completely consistent, improving the standardization level of the product.

Simple and safe to operate: the boba pearl machine is equipped with an emergency stop button and is easy to operate. One worker can perfectly control the machine.

The working principle of boba pearl maker machine

Feeding process: the feeding port is kneaded dough with a smooth surface. First, ensure that the kneaded dough conforms to the machine’s production, forms a ball, does not stick to the mixing barrel, cuts into strips and does not stick to the knife, and the softness and hardness are suitable, then knead into strips and pat. It is not easy to deform when held flat in the hand. If you have any trouble with dough mixing or pressing, please consult our commercial dough mixer.

Pressing part: the rotating pressing wheel squeezes the dough into a sheet of a certain thickness. This thickness is the diameter of the boba pearl. Before starting the machine, do not put tapioca starch in the dry powder box, but put glutinous rice flour to prevent the material from slipping and sticking to the pressing wheel.

Forming system: it mainly consists of special cutting tools to cut boba pearls into round or oval shapes. When turning on the machine, first set the cutter speed at around 45HZ, and use the speed of the pressing surface to match the speed of the cutter. If the pressing speed is too fast, it will be rounded into a round shape or the material will be blocked, and all the materials will be ejected from the waste outlet. If the pressing speed is too slow, the meatballs will become incompletely round or half-shaped.

The cutting speed and pressing speed can be adjusted by the customer.

Specifications of boba tapioca pearls machine

| Mode | TZ-1200 |

| Voltage | 220v/380v |

| Power | 0.55kW |

| Capacity | 50-100kg/h |

| Diameter Range | 6-22mm |

| Size | 1350*900*850mm |

| Weight | 220kg |

FAQ of tapioca pearls machine

What is the material of the machine?

The parts of the pressing wheel and forming wheel that mainly come into contact with processed food materials are made of 304 stainless steel, and the shell and guide hopper of tapioca pearls machine are made of 201 stainless steel.

Machine voltage details?

The machine uses AC alternating current, single-phase power 220v, it can be changed to three-phase power 220v, but it is not recommended.

Can the diameter of the produced boba pearls be adjusted?

One machine corresponds to one diameter parameter, and the diameter of the boba pearl is not adjustable.