The main function of the dough dividing machine is to evenly divide the dough into small pieces or specific shapes for further processing into various pasta products. It efficiently produces weight-stable dough and is widely used in baking and catering applications.

Dough cutter machine working video

Structure of dough dividing machine

- Feed port: the raw material of the feed port is dough.

- Dividing device: the core part cuts the continuous dough into small pieces or specific shapes through rotating cutters and molds. This step is automatic and continuously produces dough pieces that can be precisely cut according to preset weights.

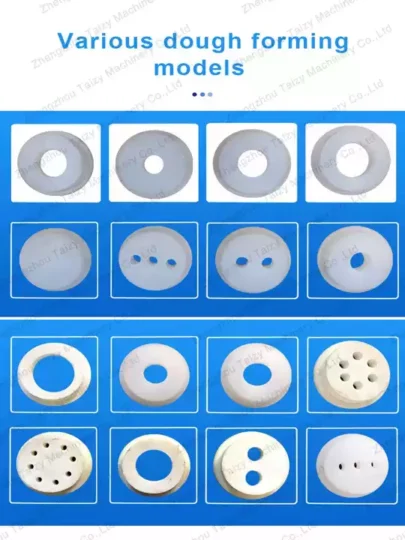

- Forming mold: it can be replaced. It can be made with one hole, two holes, or three holes. The shape and number of dough pieces formed by different molds may vary.

- Output and collection: the cut dough pieces will fall directly into the collection tray to facilitate subsequent manual or automated processing.

FAQ of dough divider machine

What material is the feeding system made of?

It is made of copper, but it can be made of 304 stainless steel if the customer needs it.

What is the maximum diameter of dough that can be processed?

This dough divider divides dough according to weight, so the size of the dough may be irregular. The diameter of the dough depends on the size of the mold.

Does an electric dough divider need an air pump?

The electric one does not need to be equipped with an air pump, but the pneumatic dough dividing machine needs an air pump to control the dough cutting more accurately.

Pneumatic dough divider

- Power: 550w

- Wight: 60kg

- Size: 60*40*75mm

- Capacity: 1pcs/s

- Process Range: 10-500g

Electric dough divider

- Wight: 60kg

- Size: 60*40*75mm

- Capacity: 1pcs/s

- Process Range: 10-500g

Application of dough divider machine

Some customers often use a dough divider when baking bread. They first divide the dough into smaller dough pieces, then put them into the fermentation box to ferment the dough, and then use toaster oven to bake the bread until it is mature.